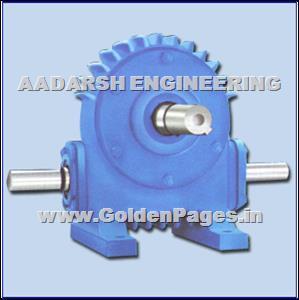

AADARSH ENGINEERING

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to AADARSH ENGINEERING

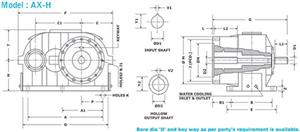

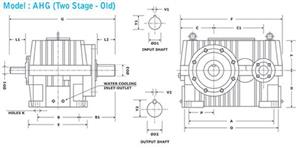

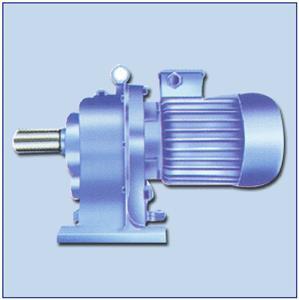

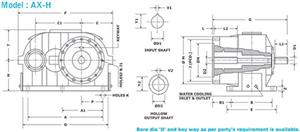

Extruder Duty Helical Gearbox

THE PRODUCTS :

Plastic Industry, at present, uses worm reduction gear boxes in extrusion and blow moulding plants, which creates many problems continous production works. Like oil leakage, over heating, noise, wear & tear of bronze worm wheel, etc...

In addition to that this gear box requires separate bearing bousing to withstand thrust load of screw. To over come this problem we have launched specially developed helical gear box with in-built thurst bearing, which gives you following advantages.

1. No need for separate thrust housing & bearing.

2. Easy alignment (screw directly fits into the vore of gear box)

3. Easy to assemble & dismantle.

4. Very heavy duty spherical roller thrust bearing is used.

5. Cost saving.

6. Power saving. (you may save up to 20 % power.)

7. Less requirement of space.

8. For bigger sizes water cooling is provided for better efficiency of gear box.

9. No maintenance required except periodic oil level checking.

10.Higher productivity compare to worm reducer.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.